Port Cranes

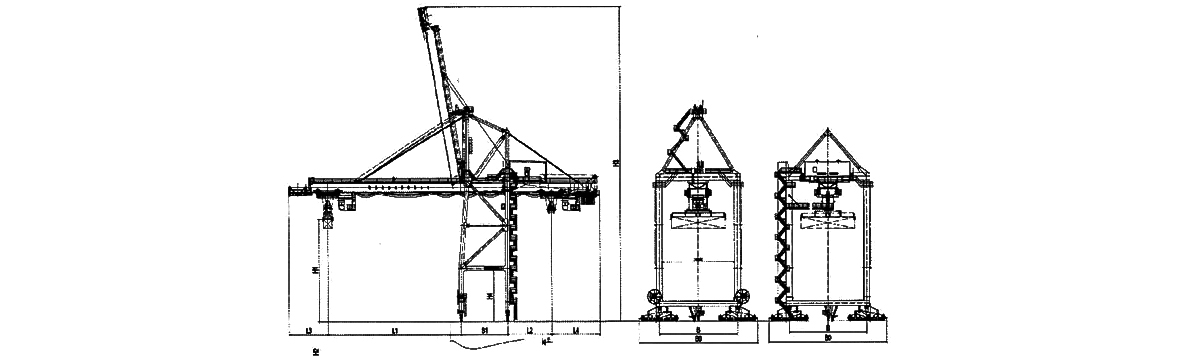

Ship to shore quay crane, also known as STS crane is the core lifting equipment at the front of the container terminal. The quay gantry crane is the key to the efficient operation of modern ports. It looks like a precise and strong giant, specializing in loading and unloading container ships. The main function is to seamlessly connect the logistics transfer between ships and terminals. Quay container cranes could easily unload containers directly from ships to terminals, or vice versa. And then it is capable of loading containers accurately and precisely from terminals to ships to safeguard the smoothness of container transportation.

The metal structure has high strength and excellent stability, providing solid support for the whole equipment. No matter how much load it faces, it can be as stable as a mountain, guaranteeing the safe operation of the equipment.

Weihua quay crane is in strict compliance with international standards such as FEM, DIN, IEC, AWS, GB, etc. This series of high standards ensures the quality and international leading level.

Its electrical control system takes advanced technology, through the all-digital AC frequency conversion, and PLC control speed regulation. STS quay crane realizes the flexible command and precise control of various institutions. This ensures that every action is accurate, showing a high degree of coordination and precision.

The lifting mechanism has strong power to cope with 35-ton to 65-ton and other different lifting capacities of the container. Whether it is full of heavy containers or empty containers, it ensures a smooth and safe lifting process. The trolley running mechanism can make the trolley move freely and accurately on the bridge. This ensures the precise horizontal transfer of containers between the ship and the terminal. The tilting mechanism adjusts the working angle according to different operation scenes and ship types. This adjustment makes the operation more convenient and efficient. And gantry running mechanism ensures quay crane runs stably on the quay front rail and realizes the forward and backward movement. Thus, it could easily cope with the loading and unloading needs of ships in different positions.

Trolley assembly is a key link to carry and move containers, and other institutions with a perfect fit. The tilting and hanging cabin protection device is the “safety guard” of the equipment. In the face of unexpected situations such as container hanging cabins, it can quickly activate the protection mechanism. It is capable of effectively preventing the equipment from being damaged, safeguarding safety and preventing the occurrence of safety accidents. In addition, there are a series of auxiliary devices, to further improve the overall function and enhance the convenience and safety of operations.

Our quay crane has various specifications of single and double container spreaders to meet the needs of different operational scenarios. Moreover, the electronic anti-shaking function can also be optional according to customer demand. This function could effectively reduce the shaking of containers and further improve operational efficiency and stability.

Weihua quay crane stands out in the industry with its excellent technology. It adopts frequency conversion multi-transmission feedback technology. This advanced technology improves the performance of the whole machine. It not only has a large lifting capacity and long front reach to cover a wider operating range but also can collect real-time running position information to realize intelligent control of spreader trajectory.

| Main Technical Parameters | |||||||||||

| Basic Parameters | Rated Lifting Capacity | Under Spreader | 35 | 41 | 51 | 65 | t | ||||

| Under Hook | 45 | 50 | 61 | 75 | t | ||||||

| Lifting Height | Above Rail | 37 | 25 | 50 | 35 | 58 | 40 | 62 | 42 | m | |

| Below Rail | 12 | 15 | 18 | 20 | m | ||||||

| Front Outreach | 30 | 45 | 51 | 65 | m | ||||||

| Rear Outreach | 10 | 15 | 15 | 25 | m | ||||||

| Rail Gauge | 16 | 16/22 | 30.48 | 30.48 | m | ||||||

| Total Trolley Travel Distance | 56 | 76/82 | 96.48 | 120.48 | m | ||||||

| Inside Clearance Between Legs | ≥17.5 | ≥17.5 | ≥18.5 | ≥18.5 | m | ||||||

| Clear Height of Middle Cross Beam | ≥13 | ≥13 | ≥13 | ≥13 | m | ||||||

| Distance Between Gantry Bumpers | ≤27 | ≤27 | ≤27 | ≤27 | m | ||||||

Speed Parameters | Lifting Speed | Full Load | 50 | 60 | 75 | 90 | m/min | ||||

| No Load | 120 | 120 | 150 | 180 | m/min | ||||||

| Trolley Traveling Speed | 180 | 210 | 240 | 240 | m/min | ||||||

| GantryTraveling Speed | 45 | 45 | 45 | 45 | m/min | ||||||

| Boom Hoisting Time (One Way) | 5 | 5 | 5 | 5 | min | ||||||

The items listed in the above technical parameter table are for reference.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request