Chain Bucket Ship Unloader

- Capacity:400-3000T

- Power supply mode:Cable drum/safety sliding contact line

- Recommended steel track:Q80/Q100

- Brand: WeiHua

- Product Type:Mining machinery

Advantages of Chain Bucket Ship Unloader:

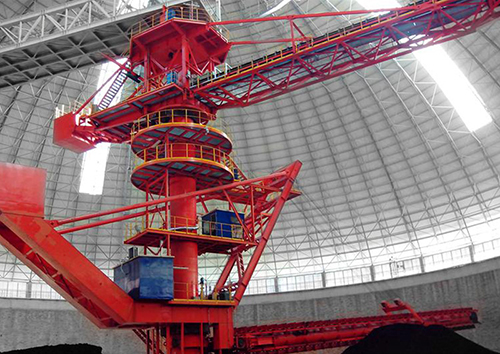

Chain Bucket Ship Unloader is a continuous bulk material unloader that uses chain buckets to excavate materials from the cabin and unload them to the wharf through an on-board conveyor system.

The chain bucket ship unloader is mainly composed of the following parts: chain bucket reclaiming and lifting mechanism, bucket elevator head rotating mechanism, material receiving mechanism, boom rotating mechanism, boom pitching mechanism, walking mechanism and belt conveyor system Wait. During the unloading operation, the chain bucket digs up the material from the cabin, and then unloads it into the receiving mechanism by lifting, then transfers it to the belt conveyor in the boom, and finally enters the pier on the wharf through the center funnel and the discharge belt conveyor. Belt conveyor system.

Advantages of Chain Bucket Ship Unloader:

- High unloading efficiency: The average unloading efficiency of the ship unloader included in the cleaning stage can reach more than 0.55~0.60 of the rated productivity, while the grab ship unloader is usually only 0.45~0.50.

- Less pollution to the environment: Except for the reclaimer head, the material conveying path is basically closed, and the dust is not easy to escape. There is no frequent starting and braking operations during work, so the noise is not large.

- Low energy consumption: According to statistics, its specific energy consumption is 1MJ/t~1.26MJ/t, while the grab ship unloader is 1.62MJ/t~1.8MJ/t.

- Small quality: its quality is generally smaller than that of grab ship unloaders (especially trolley-type grab ship unloaders) with the same outreach and productivity. 5. Stable work: because it is a continuous way of working.

- The operation is easy to realize automation: the reclaiming process of the ship unloader on each working surface is similar, so the operation is convenient and it is easy to realize semi-automation and automation.

Chain Bucket Ship Unloader can be used to unload limestone, coal, phosphate, ore and raw sugar and other materials. The maximum unloading capacity has exceeded 3000t/h, and the maximum ship type for unloading is 100,000-ton sea-going ships.

Equipment model | Unit | LSU 400 | LSU 600 | LSU 800 | LSU 1000 | LSU 1500 | LSU 1800 | LSU 2000 | LSU 3000 |

Production capacity | t/h | 400 | 600 | 800 | 1000 | 1500 | 1800 | 2000 | 3000 |

Applicable materials | - | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. | Coal, coke, limestone, bauxite, iron ore, pellet ore, clay and other bulk materials. |

Density(Material) | t/m³ | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 |

Particle size(Material) | mm | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 |

Traveling speed of cart | m/min | 0.1-20 | 0.1-20 | 0.1-20 | 0.1-20 | 0.1-20 | 0.1-20 | 0.1-20 | 0.1-20 |

Rotating speed(Hoisting chain bucket) | r/min | 0-0.45 | 0-0.45 | 0-0.45 | 0-0.45 | 0-0.45 | 0-0.45 | 0-0.45 | 0-0.45 |

Chain speed(Hoisting chain bucket) | m/s | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 | 0.2-1.65 |

Rotating angle | ° | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 |

Rotating radius (Cantilever crane) | m | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 |

Rotating speed (Cantilever crane) | r/min | 0.-0.09 | 0.-0.09 | 0.-0.09 | 0.-0.09 | 0.-0.09 | 0.-0.09 | 0.-0.09 | 0.-0.09 |

Pitching angle (Cantilever crane) | ° | 38~-18 | 38~-18 | 38~-18 | 38~-18 | 38~-18 | 38~-18 | 38~-18 | 38~-18 |

Rail gauge: | m | 12.5 | 15 | 16 | 20 | 22 | 25 | 25 | 30 |

Maximum wheel load | KN | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 |

Recommended steel track | Q80/Q100 | Q80/Q100 | Q80/Q100 | Q80/Q100 | Q80/Q100 | Q80/Q100 | Q80/Q100 | Q80/Q100 | |

Power supply mode | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | Cable drum/safety sliding contact line | |

Contact mode | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | Cable drum/safety sliding contact line/wireless | |

Control mode | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action | PLC program control, manual and single action |