News

Quay Crane, also known as Ship to Shore Crane or Quayside Container Crane, is a heavy lifting equipment designed for port terminals. Quay Crane is usually installed on the shore of the port terminal and can efficiently and quickly load and unload container ships. It is an indispensable and important equipment for modern ports. This article will introduce you structure, working principle, helping you understand the quay crane definition. Please read on.

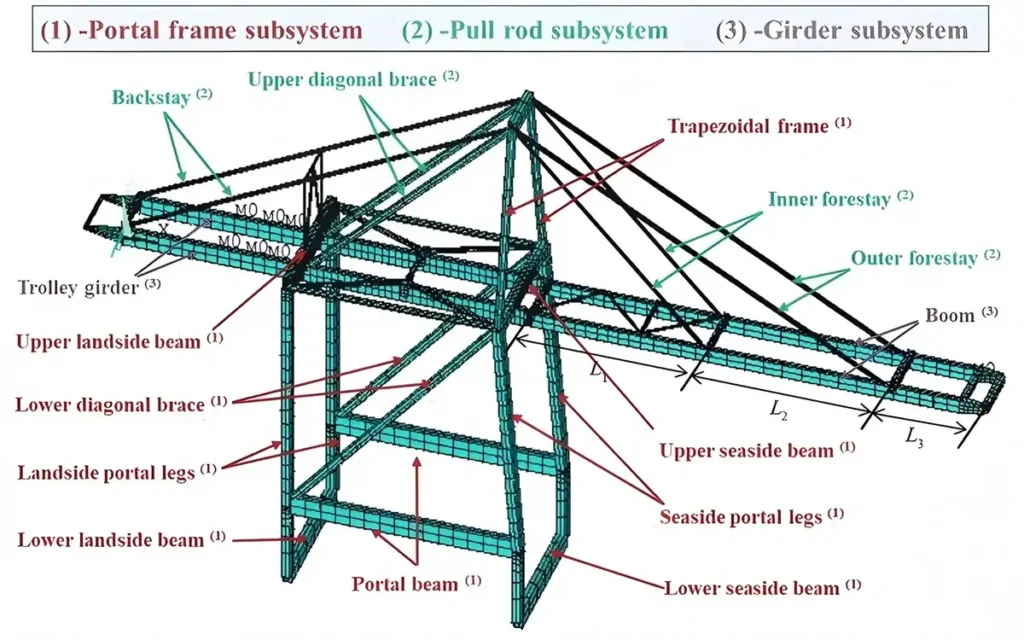

Quay Crane is mainly composed of large trolley operating mechanism, small trolley operating mechanism, hoisting mechanism, pitching mechanism, slewing mechanism, metal structure, electrical system and safety protection devices. The structural characteristics of each component are as follows:

1. Metal Structure:

Include Front Boom, Rear Boom, and Portal Frame.

2. Hoisting System:

Adopts wire rope + pulley set, equipped with a variable frequency motor to realize precise hoisting. The double spreader model is equipped with a differential gearbox, which can lift two 40ft containers independently or synchronously.

3. Trolley Traverse:

Moving along the main beam track, the speed can reach 240m/min, adopting a traction type or a self-propelled type.

4. Boom Luffing:

Hydraulic or wire rope driven, the front beam angle can be adjusted.

5. Crane Travelling Mechanism:

Moving along the dock track, equipped with windproof devices, such as rail clamps, the speed is usually 30-45m/min.

6. Quay Crane Spreader:

Container spreader with spinlock (Twistlock) automatic locking box, can be shifted sideways, equipped with an anti-swaying system, and accurate alignment.

7. Electronic Control System:

High-voltage cable reel (6kV-24kV) or slip line power supply. Frequency control motor, overload protection, anti-collision, emergency stop interlocking, and wind resistance device.

8. Auxiliary Structure:

Cab with the trolley to move, providing a panoramic view of the operation of the field of vision, built-in electrical cabinets in the Machine House, a hydraulic station, and some models are equipped with photovoltaic power generation.

| Basic Parameters | Rated Lifting Capacity | Under Spreader | 35 | 41 | 51 | 65 | t | ||||

| Under Hook | 45 | 50 | 61 | 75 | t | ||||||

| Lifting Height | Above Rail | 37 | 25 | 50 | 35 | 58 | 40 | 62 | 42 | m | |

| Below Rail | 12 | 15 | 18 | 20 | m | ||||||

| Front Outreach | 30 | 45 | 51 | 65 | m | ||||||

| Rear Outreach | 10 | 15 | 15 | 25 | m | ||||||

| Rail Gauge | 16 | 16/22 | 30.48 | 30.48 | m | ||||||

| Total Trolley Travel Distance | 56 | 76/82 | 96.48 | 120.48 | m | ||||||

| Inside Clearance Between Legs | ≥17.5 | ≥17.5 | ≥18.5 | ≥18.5 | m | ||||||

| Clear Height of Middle Cross Beam | ≥13 | ≥13 | ≥13 | ≥13 | m | ||||||

| Distance Between Gantry Bumpers | ≤27 | ≤27 | ≤27 | ≤27 | m | ||||||

Speed Parameters | Lifting Speed | Full Load | 50 | 60 | 75 | 90 | m/min | ||||

| No Load | 120 | 120 | 150 | 180 | m/min | ||||||

| Trolley Traveling Speed | 180 | 210 | 240 | 240 | m/min | ||||||

| Gantry Traveling Speed | 45 | 45 | 45 | 45 | m/min | ||||||

| Boom Hoisting Time (One Way) | 5 | 5 | 5 | 5 | min | ||||||

Lifting and Lowering: Quay Crane realizes container handling from ship to quay (or vice versa) by vertical lifting and lowering of the spreader driven by a frequency converter motor through the wire rope pulley system of the lifting mechanism. The double spreader model can operate two 40-foot containers synchronously to enhance operational efficiency.

Trolley lateral movement: The trolley carrying the spreader runs horizontally along the main girder track (speed up to 240m/min), accurately locates above the container, and combines with the lateral movement of the spreader (±800mm) and the Twistlock mechanism to complete the grabbing and releasing of the container.

Beam tilt adjustment: The angle of the front beam (usually 5° to +80°) is adjusted by a hydraulic or wire rope-driven tilt mechanism to adapt to the operating height of different ship types, and the beam can be tilted up to reduce wind resistance during non-operating time.

Traveling and positioning of the large vehicle: the whole machine moves along the quay track, equipped with rail clamps and anchoring devices to ensure stable wind resistance.

Automation control: The automated shore bridge integrates PLC and AI dispatching system, which can automatically optimize the path and has anti-sway positioning, and some models are equipped with laser scanning and OCR (box number recognition) for unmanned operation, which is usually used in smart port operations.

Ship-to-shore cranes, as the core equipment of modern container terminals, have highly efficient loading and unloading capacity, a precise positioning system, and intelligent control technology, which significantly improves the efficiency of port operations and reduces logistics costs. Through the above detailed introduction of the definition, structure, and working principle of the shore bridge crane, I believe you have a basic understanding of this equipment. If you want to know more about the technical details of the shore bridge crane or customized solutions, welcome to contact Weihua's technical team.

Submit Request