News

An overhead crane is a lifting equipment that spans a fixed track in a workshop, warehouse, etc. It consists of a bridge, a lifting trolley, and a running mechanism that can run along the tracks at both ends, and is commonly used for efficient lifting of heavy loads indoors. This article will systematically introduce 3 common types of overhead cranes, including the basic parameters, characteristics, applications, etc., of various types.

Single girder design, hoist or lifting trolley running below the single girder, suitable for lighter lifting operations, lifting capacity between 1 and 20 tons. It is characterized by simple structure, light weight, low manufacturing cost, and easy installation and maintenance. Suitable for lower building heights, such as small and medium-sized factories, warehouses, and other places to carry and load small and medium-sized objects.

Single Girder Overhead Crane

Double main girder design, the lifting trolley runs between two main girders, suitable for heavier lifting tasks, lifting capacity of 20~500 tons. It has the features of sturdy structure, strong loading capacity, and stable operation, and is suitable for handling and loading, and unloading heavy goods in large-scale factories, steel mills, power plants, wharves, and other places.

Double hook block for bridge crane

Single main girder design, suspended from the building roof I-beam structure, moving along the suspension track. Suitable for light lifting operations, usually with a lifting capacity between 1 and 10 tons. Characteristics: flexible installation, adaptable, suitable for building height of low space, such as light factories, workshops, warehouses, and other places to carry and load light goods.

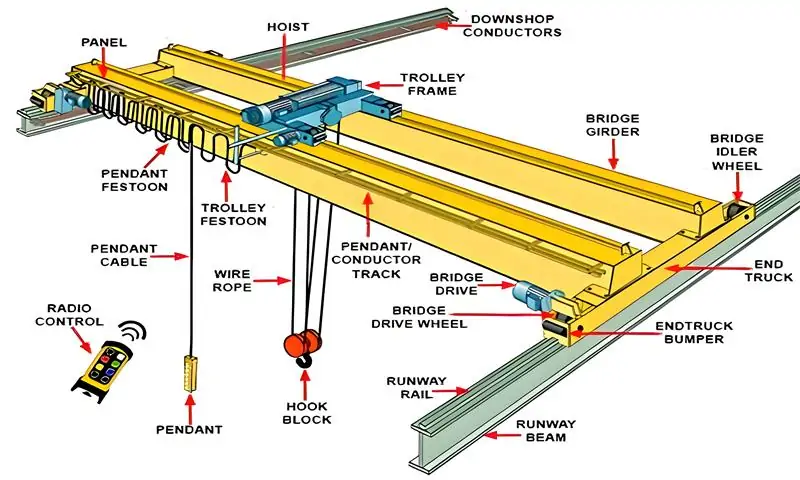

Although there are more types of overhead cranes, their basic structure is the same. The bridge crane is mainly composed of the beam, a lifting device, end beam, beam traveling mechanism, a lifting device traveling mechanism, a rail and electrical power, a control device, and other components.

Overhead travelling cranes are used to lift, transport, and position heavy loads in a variety of industrial environments, with a lifting range of 1-500 tons. They are widely used in manufacturing (steel coils, machine assembly), warehousing (container handling), metal processing (molten material transfer), energy (turbine maintenance), and construction (prefabricated parts installation). Special models are available for extreme conditions (explosion-proof, high-temperature environments). Specific types can all be customized to meet specific needs.

Through the introduction of this article, you have understood the structural characteristics, load carrying capacity and applicable scenarios of the three main types of single girder overhead travelling cranes, double girder overhead travelling cranes and suspension cranes.

The following are recommendations for selection:

If you need a customized overhead crane solution, please contact our team of engineers for a free selection consultation.

Submit Request