News

The overhead cranes are widely used in industries such as factories, warehouses, and construction sites for precisely lifting heavy materials. The correct operation and use of overhead cranes is very important for the safety of your business, otherwise, one wrong move can lead to costly accidents, delays, and even injuries. This guide will give you a detailed overview of how to use overhead crane, including how to operate, considerations, and more. Please continue reading this article:

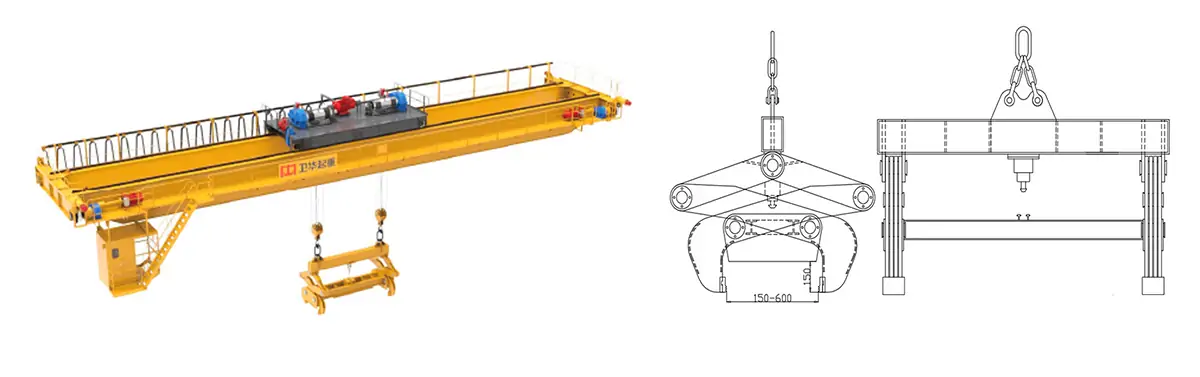

The overhead crane is a kind of lifting equipment for lifting materials above the span of workshops, warehouses, and factories. It consists of a main girder and parallel rails, the ends of which are mounted on tall concrete columns or steel structures, shaped like a bridge, hence the name “Bridge Crane”.

The overhead crane is mainly composed of the main girder, driving device, running mechanism, hoisting mechanism, driver control system, metal structure, and so on. The working principle of the overhead travelling crane is to realize precise material handling through an electric drive system.

Its working process is as follows: the motor drives the hoisting mechanism reel to rotate through the gearbox drive, and realizes the vertical lifting and lowering of the spreader through the wire rope pulley set; the trolley running mechanism drives the crane to move longitudinally along the plant track, and the trolley running mechanism drives the hoisting mechanism to run transversely on the main girder of the bridge. The driver coordinates the action of each organization through the linkage table control system, and cooperates with the safety components such as limit switches and brake devices to complete a series of operation cycles, such as lifting, panning, positioning, unloading, and releasing heavy loads. The whole system adopts a modularized design, and the electrical control realizes stepless speed regulation to ensure the smooth running of the load and meet the precise lifting requirements under different working conditions.

The overhead crane usually has three methods of operation and can be used individually or in combination. These include the console, remote control, and joystick. Below are their functions and specific methods of operation:

1. Cab control: The cab is usually located under the main crane beam or side, and the operator in the cab can visualize the lifting process. Through the console, the operator can operate the handle or button to realize the control circuit of the various crane mechanisms, including the start, speed control, direction change, braking, and other functions. The cab is equipped with limit switches, emergency stop buttons, load limiters, etc., which is suitable for workshops with large spans or high-precision lifting needs.

2. Remote control (remote control): wireless/wired control, the effective range is usually 50-100 meters, with an emergency stop function, automatically cuts off the power supply when the signal is interrupted to prevent misoperation. The operator can move with the crane on the ground, remote control buttons control lifting, walking, and with gesture commands, suitable for narrow spaces or multiple equipment cross-operation.

3. Joystick control: through the mechanical or electronic joystick, directly control the motor action, usually with single-speed and double-speed buttons. Switch the joystick to “running” mode, push forward/pull back the joystick to control the lifting/lowering, and tilt left/right to control the movement of large or small vehicles. Commonly used for small overhead cranes or auxiliary lifting equipment, suitable for short distances and frequent starting and stopping handling tasks, such as material turnover operations in the workshop.

The correct operation procedure of overhead cranes directly affects the operation safety and efficiency. The following are the operation procedures and precautions for overhead cranes:

Following the above operating procedures and precautions can effectively improve work efficiency while safeguarding the safety of personnel and equipment. It should be noted that the specific operation details may vary according to different overhead crane types and manufacturers' requirements. Please refer to the operation manual of the specific equipment for operation.

Weihua is a leading overhead crane manufacturer and supplier in China, is committed to providing customers with comprehensive one-stop lifting solutions, including product program design, installation services, and professional technical consulting of the full range of support. If you still have questions about how to operate overhead cranes safely and efficiently after reading this information, please feel free to contact our professional technical team. We will provide you with timely and professional answers and guidance.

Submit Request