Grúas portuarias

Rubber Tyred Gantry Crane (RTG for short), is a kind of special lifting equipment dedicated to stacking operations in container yards. It is mainly used for lifting, moving and stacking containers, and is widely used in ports and large logistics centers, etc. Rubber Tyre Gantry Crane adopts rubber tires as the travelling device, which provides high mobility flexibility in the yard, and can be quickly moved between different rows and columns to adapt to busy loading and unloading demands.

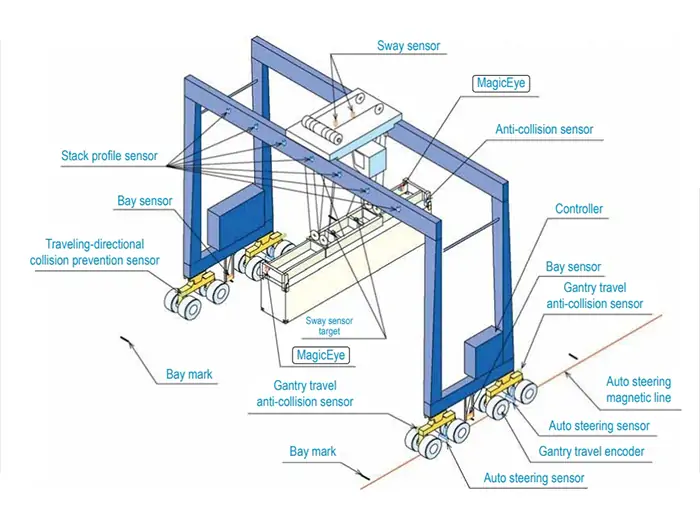

Rubber Tyred Gantry Crane is usually equipped with special container telescopic spreader, which can safely and efficiently handle 20ft, 40ft, 45ft containers.RTG integrates automation technology, such as automatic positioning system and anti-sway control system, which effectively improves the safety and efficiency of operation.

Rubber Tyred Gantry Crane can be divided into 2 types of diesel-electric and diesel-hydraulic, according to the driving method, and the differences are as follows:

It is powered by diesel-driven generators, electric motors drive the various mechanisms; with high energy utilization, frequency conversion speed regulation, easy maintenance, and suitable for the modern green port needs. It is characterized by high energy utilization, frequency control, easy maintenance, suitable for long-time continuous heavy load operation, and better environmental protection than pure diesel drive.

It is driven by a diesel engine hydraulic pump, power transmission through the hydraulic system; has a compact structure, fast response, flexible layout, smooth starting and stopping, strong overload resistance, but lower efficiency, suitable for small and medium-sized or intermittent operation scenarios, maintenance complexity is higher.

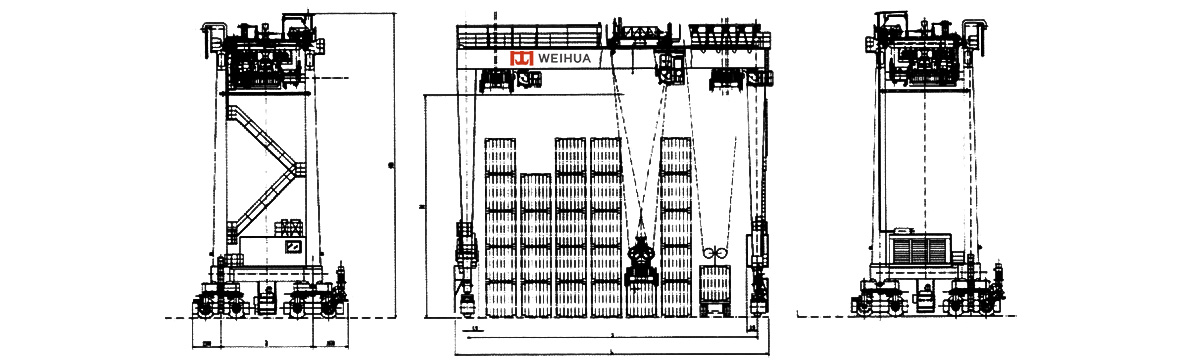

Rubber Tyred Gantry Crane consists of gantry bracket, power transmission system, hoisting mechanism, traveling mechanism, trolley running mechanism, trolley running mechanism and special container spreader. The following are the functional characteristics of each component:

Portal Bracket

Heavy-duty steel structure frame to support the whole machine and provide working space, usually with box beam design, featuring high strength and good torsion resistance.

Power Transmission System

Mostly adopts diesel-electric hybrid or all-electric drive, equipped with frequency conversion control to realize efficient energy conversion and smooth speed regulation.

Mecanismo de elevación

It is composed of motor, reducer, reel, and wire rope, adopting a double or multiple reels design, supporting fast lifting and lowering of containers, equipped with load sensor and height limiter, providing accurate positioning and overload protection.

Traveling Mechanism

Tire-type design, equipped with a hydraulic or electric drive system, with a variety of steering modes, to adapt to the demand of flexible transfer in the yard, some models are equipped with an automatic deflection correction system.

Trolley running mechanism

It controls the longitudinal movement of the whole machine along the yard, adopts the structure of multi-wheeled balancing beam to disperse the wheel pressure and reduce the damage to the yard floor, and is equipped with anti-collision and anchoring devices.

Trolley running mechanism

Drive the spreader to move transversely along the main beam, adopting rack and pinion or steel wire rope traction mode, with a precise positioning system (such as laser distance measurement), the error of the spreader to the box is ≤±10mm.

Specialized container spreader

Equipped with a rotary locking device as standard, it can automatically or manually lock the corner pieces of containers, and supports the switching of various box types from 20ft to 45ft, and part of the spreader integrates the functions of weighing and tilt angle detection.

| Principales parámetros técnicos | ||||

| Capacidad de elevación nominal (toneladas) | 35 | 41 | 70 | |

| Distancia base (metros) | 7 | 7 | 7.5 | |

| Span (Metro) | 23.47/26 | 23.47/26 | 23.47/26 | |

| Altura de elevación (metros) | 15.5/18.5 | 15.5/18.5 | 15.5/18.5 | |

| Apilar capas | 4/5 | 4/5 | 4/5 | |

| Especificación del contenedor | 20',40',45' | 20',40',45' | 20',40',45' | |

Velocidad | Elevación (carga completa/carga vacía) | 20/40 | 25/50 | 25/50 |

Desplazamiento del pórtico (carga completa/carga vacía) | 30/130 | 30/130 | 30/130 | |

| Viajar en tranvía | 70 | 70 | 70 | |

| Números de rueda | 8 | 8/16 | 16 | |

| Carga máxima por rueda | 300 | 320/180 | 200 | |

| Fuente de alimentación | Grupo electrógeno diésel o trifásico AC380V 50Hz | |||

The items listed in the above technical parameter table are for reference.

Weihua's RTG Rubber Tyred Gantry Crane is multi-functional and highly efficient, reducing container-handling time and enhancing overall operational efficiency in ports or logistics hubs, stable under heavy loads and reliable during long-term operation to minimize breakdown risks. They have an extensive operation range and remarkable maneuverability, being able to travel straight, laterally, make 0 - 90 degree turns, and turn in a place with ease to adapt to different container storage layouts and complex working environments, and are less affected by ground unevenness. Their operation is user-friendly with a simple interface for quick proficiency. Also, the maintenance is easy with accessible components and a clear procedure, reducing downtime and costs.

There is a comprehensive safety indication system giving clear warnings and an effective overload protection device responding promptly to overloads. The electric drive system uses full digital AC variable frequency and PLC speed control technology for flexible and accurate control. This allows smooth speed adjustments and precise control of gantry, trolley, and spreader movements for accurate container handling. We use standard components from renowned domestic and international brands that are rigorously tested for excellent performance and durability to ensure long-term stable operation and reliability.

No dude en dejarnos un mensaje. Le responderemos en 24 horas.

Enviar solicitud