Ersatzteile für Kräne

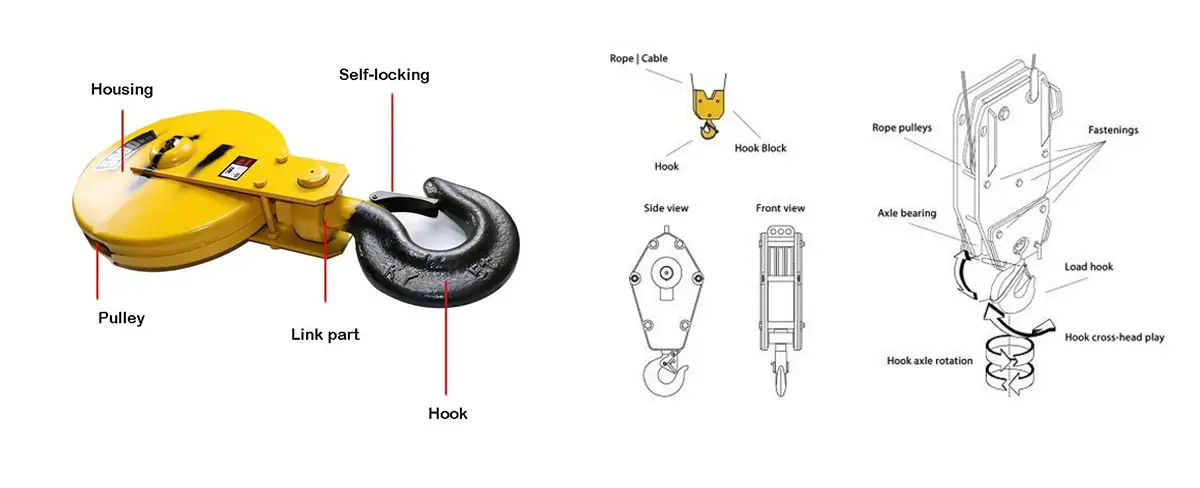

Lifting Crane Hook Block is an integral part of the hoisting mechanism of overhead cranes and gantry cranes and is suspended from the wire rope of the hoisting mechanism. As the primary load handling device, the Crane Hook Block is often used in conjunction with electric hoists and winches for the common lowering of hooks for gripping and lifting loads. Crane Hook Blocks are supplied as standard with a hook safety locking pin and an integrated pulley (single or multiple) to increase lifting efficiency.

Weihua can provide all kinds of crane hook blocks, including light hooks (0.5t-20t), heavy hooks (20t-500t), forged hooks, laminating hooks, and specialized hook sets for special conditions. All crane hook models can be customized, including load capacity and color. We support factory SGS inspection before shipment. Our technical team can provide you with the best lifting solutions. For product selection or technical consultation, please feel free to contact us.

Crane Hook Blocks can be divided into two main types according to their structural form: single crane hook block and double crane hook block. Their structures and application scenarios are as follows:

| Rated Load | Size(mm) | Wire RopeDia.(mm) | Dead Weight | |||

| A | B | H | øD | |||

| 3.2T | 575 | 341 | 426 | 300 | 11-14 | 80 kg |

| 5T | 715 | 341 | 426 | 350 | 11-14 | 100 kg |

| 10T | 1080 | 370 | 526 | 250 | 11-14 | 200 kg |

| 16T | 1330 | 500 | 660 | 310 | 14-20 | 330 kg |

| 20T | 1415 | 515 | 653 | 500 | 16-20 | 460 kg |

| 32T | 1740 | 620 | 780 | 610 | 18-22 | 845 |

| 50T | 1965 | 830 | 815 | 610 | 20-22 | 1500 |

| 75T | 2335 | 970 | 1012 | 500 | 26-32 | 2500 |

| 100T | 3130 | 1360 | 1162 | 800 | 28-34 | 4200 |

| 200T | 3548 | 1617 | 1090 | 900 | 30-38 | 9100 |

The Crane Hook Block consists of a hook, hook beam, thrust bearing, hook nut, pulley, pulley shaft, side plate, safety latch, etc. The following are the detailed functions of each component:

The Crane Hook Blocks are usually used in conjunction with overhead cranes, gantry cranes, jib cranes and electric hoists, and are widely used in the following scenarios:

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen